Recognizing the Capability of Membrane Switches for Individual Interface Tools

The capability of membrane switches represents a significant improvement in customer interface style, incorporating effectiveness with aesthetic convenience. These buttons operate through a multi-layered structure that converts user interactions into electric signals, permitting for both compact layouts and strength versus ecological factors. As markets significantly prioritize user experience, comprehending the nuances of membrane layer switch modern technology comes to be vital. What effects do these improvements hold for future applications, and exactly how might they redefine user interactions across various devices?

What Are Membrane Buttons?

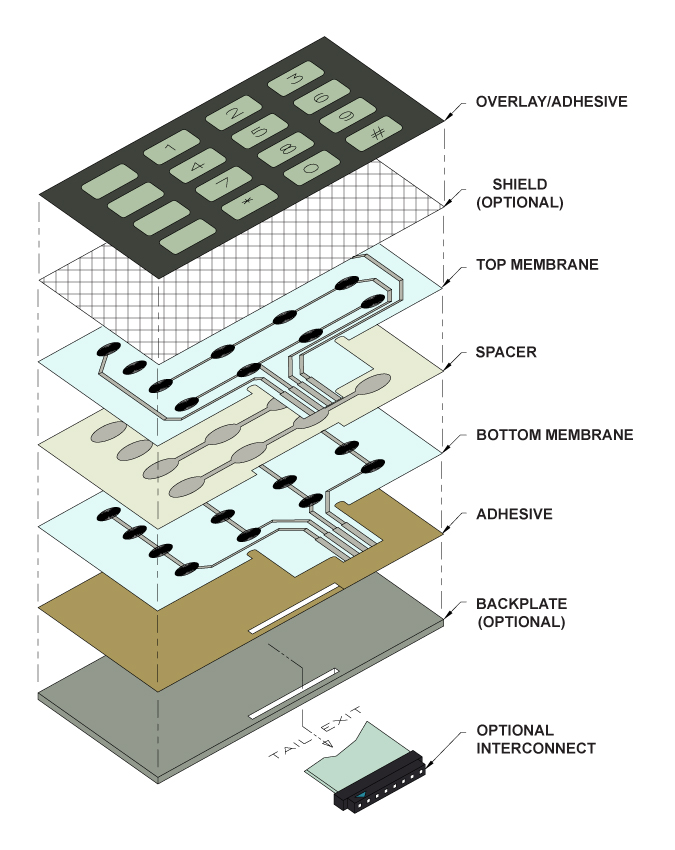

Membrane layer switches are innovative user interface devices that assist in user communication with electronic equipment. These versatile parts are composed of several layers, consisting of a graphic overlay, spacer, and a printed circuit layer. The design permits a smooth integration right into numerous digital tools, boosting both the aesthetic and functional facets of individual interfaces.

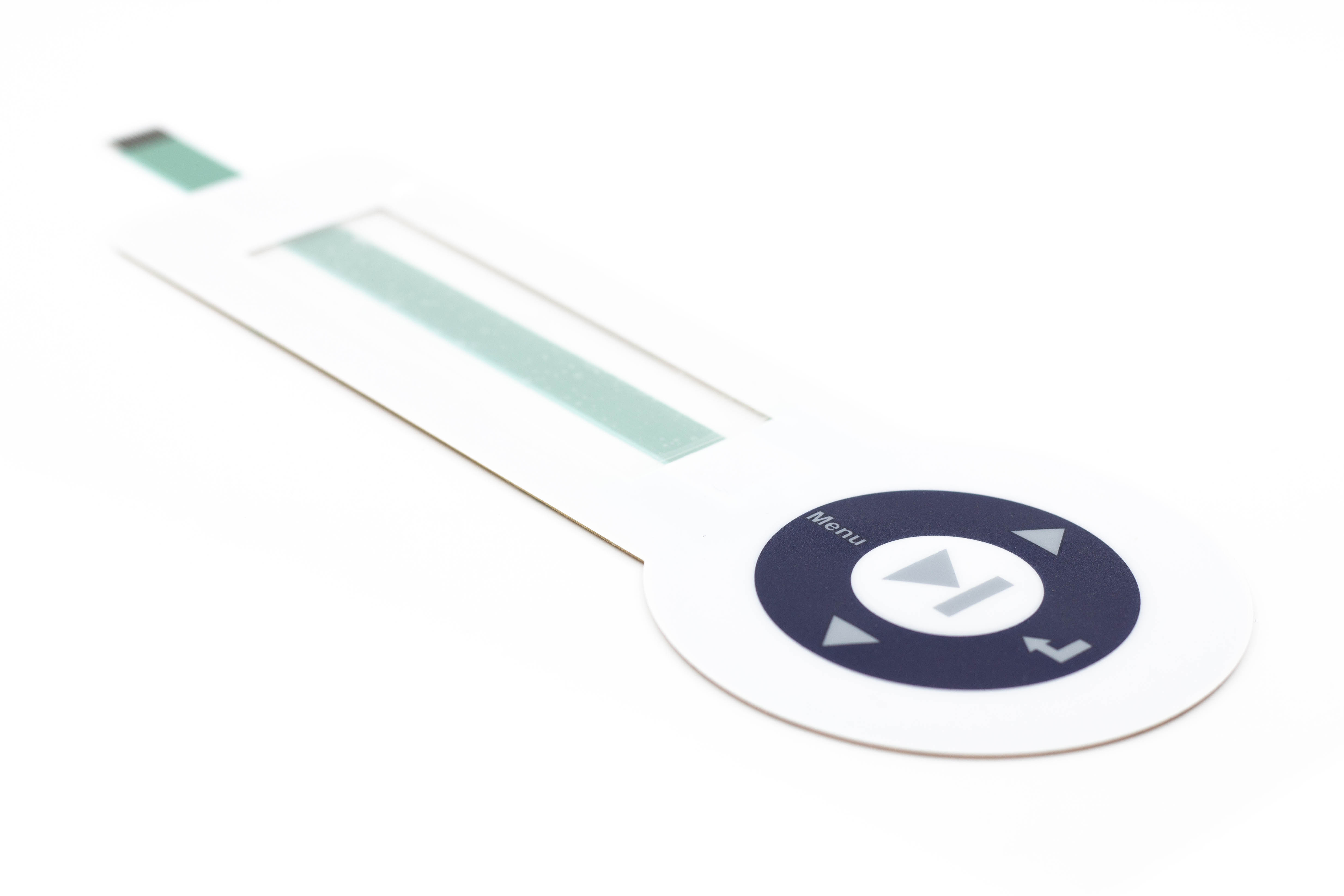

Membrane layer buttons are generally utilized in a large range of applications, from household devices to commercial machinery and medical gadgets. Their building and construction commonly features a thin profile, making them an optimal option for compact designs. The tactile comments given by these switches can be crafted to satisfy specific user choices, guaranteeing reliable communication in between the customer and the gadget.

Longevity is one more significant benefit of membrane layer switches, as they are immune to dust, wetness, and chemicals, which improves their life expectancy in requiring settings. Furthermore, these switches can be personalized in terms of form, size, and visuals layout, enabling branding and user-specific features. Overall, membrane switches stand for a useful remedy for boosting individual experience in electronic devices, integrating performance with aesthetic charm in a reliable fashion.

How Membrane Layer Switches Job

Operating on an uncomplicated principle, membrane layer changes make use of a layered construction to sign up user input effectively. Each switch includes several layers, including a published circuit layer, a spacer layer, and a top graphic layer, which are made to collaborate flawlessly. When an individual presses the top layer, it compresses the spacer layer, bringing the conductive elements of the circuit layer into call with each various other.

This contact develops a shut circuit, signaling the gadget to perform a particular function. The layout permits different arrangements, including tactile responses, which can improve the individual experience by offering a physical experience upon activation. The materials used in membrane layer switches commonly include adaptable substratums, such as polyester or polycarbonate, which make certain resilience and strength versus deterioration.

Key Benefits of Membrane Switches

Another substantial benefit is their compactness. Membrane buttons are thin and lightweight, which makes it possible for suppliers to save area in their devices without sacrificing performance. This attribute is specifically advantageous in applications where weight and volume are essential considerations.

Furthermore, membrane switches are resistant to dirt, wetness, and chemicals, enhancing their sturdiness. This resilience prolongs their lifespan and minimizes the requirement for frequent replacements, causing cost savings with time.

Furthermore, the tactile feedback offered by membrane layer buttons can be maximized to boost individual interaction. They can consist of functions such as increased switches or audible clicks, boosting use and customer experience.

Applications Across Industries

Customer interface tools making use of membrane switches are widespread in a large selection of industries, showcasing their flexibility and functionality. Membrane Check This Out Switch. In the clinical market, membrane layer buttons are integral to tools such as diagnostic devices and person monitoring systems, where their resilience and convenience of cleansing are critical for keeping hygiene standards. In the automobile industry, these buttons are used in dashboard controls and infomercial systems, giving a smooth and modern-day user interface for customers.

Additionally, the consumer electronic devices field gain from membrane layer switches in appliances and portable tools, where small design and straightforward interfaces enhance customer experience. Industrial applications also leverage membrane layer switches for control panels in machinery and automation systems, stressing their toughness and resistance to harsh settings.

In the aerospace and protection markets, membrane buttons are used in cockpit controls and devices, where dependability and performance under extreme problems are vital. In addition, the gaming sector significantly incorporates membrane layer switches in controllers and arcade equipments, adding to an engaging individual experience. Generally, the convenience of membrane layer switches over allows their widespread usage throughout numerous industries, highlighting their importance in modern interface design.

Future Trends in Membrane Switch Innovation

Furthermore, using advanced materials, such as polycarbonate and polyester movies, is expected to rise, supplying boosted longevity and resistance to ecological stress factors. These materials add to the general longevity of membrane switches, making them appropriate for harsher commercial applications.

In addition, the unification of clever modern technology, including IoT connectivity, will certainly make it possible for membrane layer switches to communicate with various other gadgets and systems, helping with a more interactive customer experience. This fad straightens with the expanding need for smart devices throughout numerous industries, from medical care to customer electronics.

Lastly, customization find out alternatives are anticipated to increase, allowing suppliers to develop bespoke options tailored to certain customer needs and choices. These advancements will certainly place membrane layer buttons as essential components in the development of customer interface modern technology.

Conclusion

In final thought, membrane changes stand for a pivotal improvement in user interface technology, providing a trustworthy and functional service for diverse electronic applications. As improvements in product scientific research and touch sensing technologies continue, the capability and applicability of membrane layer buttons are expected to increase, reinforcing my explanation their relevance in modern-day electronic devices.